SMARTRAC’S RFID SOLUTIONS ATTAINS NEW HEIGHTS

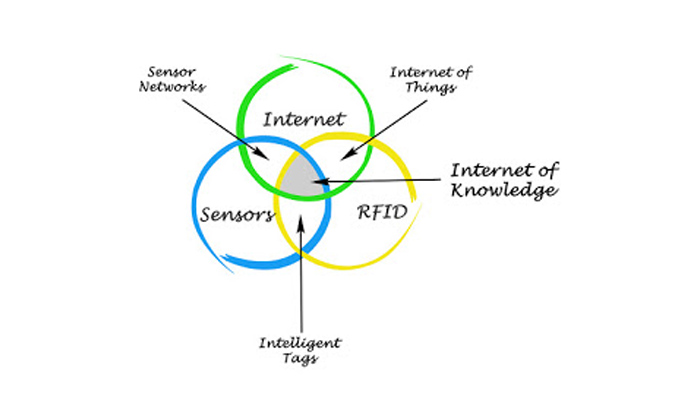

Since its inception, RFID or Radio-frequency identification technology has revolutionized the practice of asset tracking for many companies. It is an efficient and fast way to track multiple items over long distances. They are used in almost all the sectors including health, education, transportation, commerce and in various other fields. Even if you haven’t heard about it, you would still know it’s basic application – anti-shoplifting technology. Remember the alarm that sets off in a store when someone tries to steal a product? The sensors for this purpose use RFID technology.

Retailers, such as Walmart, heavily use RFID tracking tags for inventory purposes. With its wide range of applications, it has become a necessary tool for industrial operations. To further extend the use of RFID technology, SMARTRAC has launched passive sensors, SENSOR PATCH and Tadpole.

So Long To Water Leakages In Vehicles

The quality check of an automobile is the most important test that automotive industry must pass to sell their vehicle. It can make or break your whole project. A shower test is done to check whether the car has any water ingress. Previously, this was done manually, which introduced the problem of detecting the particular location of the leakage. SMARTRAC found a perfect solution for the automotive industry regarding this issue. With SMARTRAC’s Tadpole sensor, your car will remain leakage free.The sensor is an on-metal passive sensor tag designed to work on metal surfaces, with minimum signal degradation from surrounding structures.

It detects moisture and notifies its exact location. The detection area of the sensor is the tail, which guides the moisture to the sensor tag. Even minute amounts of water can be quickly detected, making it reliable and efficient for the manufacturers. Sensor Tadpole is deployed in the manufacturing flow as part of the automobile’s assembly process. Hours of manual labor while searching for a leakage is easily avoided with this RFID solution. The tag requires no power source, servicing, or replacing which makes it even more productive.

SENSOR PATCH – One RFID System Sensor, Multiple Applications

SENSOR PATCH is a passive temperature-level sensing inlay. This RFID technology is designed to precisely detect the moisture level in a given environment. With its advanced attributes, it has versatile uses. From healthcare to construction projects, SENSOR PATCH has proved to be the most efficient temperature-sensing inlay.

Here are some of its useful traits in different domains:

- For those with urinary incontinence, the industrial diaper production places the sensor inlay between the diaper layer that quickly detects the change in moisture. This RFID sensor inlay offers excellent performance, and accurately detects urine level in a diaper. It helps care facilities to work efficiently.

- In construction work, the RFID technology provides data regarding the temperature of the concrete after it has been poured. The sample estimates help in avoiding unnecessary long waits before the next slab can be poured. Thus, it reduces the wastage of time drastically.

- SENSOR PATCH is used to make high-end products for global supply chain management, industrial and logistic applications and RTIs.

SENSOR PATCH functions flawlessly on cardboard, plastics, stone, wood, construction materials. The innovative tag is a disposable, UHF, single-chip sensor inlay solution that offers cost efciency and is easy to implement.

RFID tracking has eased the working process of many sectors. The potential range of applications increases even further with improvement in data rate, storage capacity, energy consumption, and operating range. Due to its small size and low requirements, RFID technology is expected to be a groundbreaking technology that will influence our life substantially.