Are you tired of dealing with complicated cylinder systems? Say goodbye to the old ways and say hello to Trakaid! We’re here to make cylinder tracking simple and precise. In this story, we’re introducing solutions that fit your business perfectly.

Meet TRAKAID Cylotrak: Your Cylinder’s Best Friend

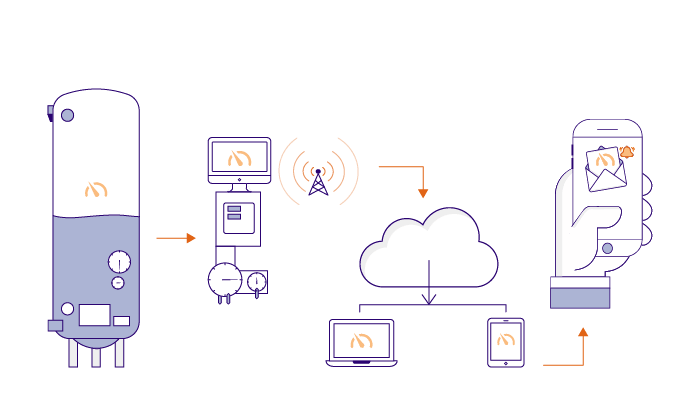

Enter a world where things make sense. Trakaid’s TRAKAID Cylotrak is not just a tool; it’s like a conductor for your cylinders. It lives in the cloud, using fancy tech to free you from manual tracking headaches. Forget about confusing ledgers—now you can enjoy real-time tracking, accurate data, and easy management.

Why Trakaid Is Awesome:

- Cylinder Identities Made Easy: Imagine each cylinder having its own unique story. Trakaid makes sure you know everything, from who made it to serial numbers and special codes. Each cylinder becomes a star with its own story.

- No More Manual Hassles: Wave goodbye to boring manual work. Trakaid’s system makes everything smooth, letting you run your business like a well-orchestrated symphony.

- Rock-Solid Data Integrity: In the big world of keeping things in order, Trakaid is like a superhero. We keep your cylinder info safe and sound, making sure everything flows smoothly.

- See Everything, Always: Trakaid gives you the power to see it all. You can optimize how you use your assets and create a masterpiece for your business.

- Safety First: Trakaid is your business’s protector. We make sure everything runs safely and follows the rules, keeping your people and customers happy.

Boost Your Business with Trakaid:

Imagine your business getting even better. With Trakaid, you’re not just getting a service; you’re getting a boost toward success. Prices start at an easy $100 per month, and we can personalize things to fit your business perfectly.

Ready to get your business in tune with the digital world? Reach out to Scott Wight at support@trakaid.com for a free chat about your business.

Easy Marking with Trakaid:

In a world where marking cylinders is a must, Trakaid has a solution that won’t break the bank. Watch how it works (https://youtu.be/jp8rD-1cFIg).

Choose Your Permanent Cylinder ID:

Why Trakaid Is Awesome:

- Barcode and QR Code Labels: Fast, customizable, and tough.

- Barcode and QR Code Name Plates: Stainless steel and easy to use.

- RFID Tags: Tough tags that scan 10X faster without needing a clear view.

Tell us what you want – barcode, RFID, nameplate, and how many – by sending a message to support@trakaid.com. We’ll give you a special offer.

Take a trip through our simple and effective cylinder tracking solution at (https://www.trakaid.com/).

Trakaid – Making Precision Easy!